2023

2023 2022

2022 2021

2021 2020

2020 2019

2019 2018

2018 Wooden Pylons

Wooden Pylons Gravity

Gravity SAOCOM 1A

SAOCOM 1A Unconscious Incompetence

Unconscious Incompetence Library 4/4: Finishing up

Library 4/4: Finishing up Library 3/4: Railings

Library 3/4: Railings Library 2/4: Floor

Library 2/4: Floor Library 1/4: Ladder

Library 1/4: Ladder SvgCanvas

SvgCanvas Conservative Toddler

Conservative Toddler AFV Taping

AFV Taping HP-35 Repair

HP-35 Repair DMP Rehosted

DMP Rehosted JS Oscilloscope

JS Oscilloscope Wrist Gears

Wrist Gears 2017

2017 2016

2016 2015

2015 2014

2014 2013

2013 2012

2012 2011

2011 2010

2010 2009

2009 2008

2008 2007

2007 2006

2006 2005

2005 2004

2004 2003

2003 2002

2002

Wrist Gears

16 January 2018

The Robotic Arm Edge is a fantastic educational kit. It comes as a box of about a hundred parts, and assembles to form a four-axis robot (plus grip, and light). There are five small DC motors, each controlled electrically by switches on the wired controller -- there are no electronics.

With one exception, the robot is very well-designed. The exception is the wrist joint. This joint only has ±60° of movement, meaning that when the arm is horizontal, the gripper can't point straight down. The reason for this limitation is a pair of linkages that transmit the motor power to the joint. Any more than 60° would result in binding as the linkages intersect.

I used Inkscape to design some gears to replace these linkages (SVG source file). I fed some scrap 3mm plywood into Google's laser cutter, and about 30 seconds later the gears were done. Much faster than 3D printing, which was the other viable option.

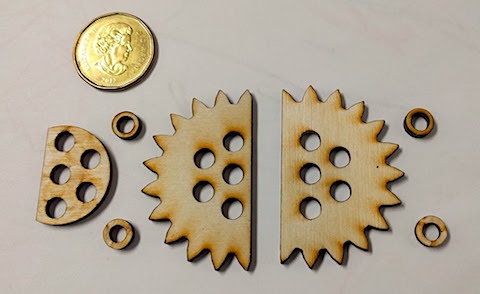

One of the gears needed a wee bit of filing in a spot where the laser didn't quite make it through the wood, but otherwise the run was perfect. Here are the finished gears (along with a spacer and some washers) with a dollar coin for scale.

Before installing the gears, some plastic around the wrist joint needed filing to increase clearances for the newly extended range of motion. The motor also needed its polarity reversed, since the addition of gears reverses the rotational direction. And with that, the joint now has ±90° of movement.

Next up, computer control...