La Salle Causeway

27 November 2024

The La Salle Causeway lift bridge was a 100 year old bridge in Kingston, Ontario. When I was 11 or 12 I spent many hours at the bridge, drawing it, hanging out with the bridgemaster, and learning how this giant machine worked. This bridge helped inspire a lifetime of engineering. A couple of years ago on a visit to Kingston I took this video of it opening. At the time nobody knew that its days were numbered.

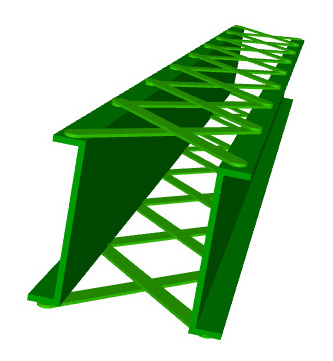

In March of this year the bridge was undergoing routine maintenance. Part of the work involved strengthening the giant beams of the A-frame that holds up the counterweight. These square beams are composed of two heavy steel side panels, held apart by cross bracing. The cross bracing was starting to rust, so needed replacing. The brain-dead workers decided to remove all the cross bracing from one of these beams. Here's the before and after:

As should be obvious, without the cross bracing, the beams are no longer stiff square elements. They are now two bendy ribbons. The result was catastrophic and the bridge buckled. As the CBC reports, it was remarkable that the entire bridge didn't collapse, killing the workers.

In the following month there was a valiant attempt to save the bridge. But it was not to be and the entire structure was demolished. Based on my childhood conversations with the bridgemaster, I understand why this was the unfortunate necessity. Even on the best of days this lift bridge was temperamental. When raised, the sun would shine on the underside of the bridge, expanding it. Thus when it was lowered a few minutes later, it would no longer engage the locking mechanism on the far side. So the bridgemaster would be forced to drop the bridge from ever increasing heights until it finally engaged. Crash. Crash. Crash. With that as the normal state of affairs, imagine trying to operate the bridge after all the major structural elements have been twisted a few degrees. There was no way that bridge could be saved.

An interesting detail that's been lost to history is that the bridge was originally manually operated. The counterweight was trimmed perfectly, so that the entire bridge could be raised by pulling on a chain looped around the drive pinion axle. The bridgemaster would pull one side of the chain to raise the bridge, then pull the other side to lower the bridge. When the bridge was eventually motorized, it was certainly more convenient (especially on cold rainy days), but it was in many ways a step backwards. The motor was only capable of being driven in one direction, so mass had to be removed from the counterweight to enable the bridge to naturally fall back down (regulated by a brake). The result was that the bridge took longer to open and close. Sometimes upgrades are downgrades.

The city of Kingston will be replacing the lift bridge soon. I hope that the new design they choose is as mechanically interesting and inspiring as the old bridge. But I'd be willing to bet that it will just be a simple slab and a couple of hydraulic pistons.